31 Jan Why RFID is the best way to improve your operational control

RFID has been around since the 1940s but has experienced a massive surge in popularity lately.

This is largely due to technological advances as well as a dramatic reduction in how much RFID systems cost to implement.

Todays RFID scanners don’t need line of site to the object that is sending out the radio frequency and the cost has dropped low enough that they’re adopted in industries as diverse as metal manufacturing and rental car agencies.

Below, we’ll walk through how RFID works and cover some of the huge massive benefits organizations can get from implementing RFID:

What is RFID tracking?

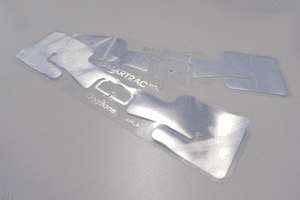

Radio Frequency Identification (RFID) systems are made up of three parts: a tag, a reader, and software.

The tags consist of an electronic circuit, which stores data, and an antenna which communicates the data via radio waves.

The reader pings the tags which sends the stored data back in response.

These responses are logged and collated by the software which organizes and provides the data on each asset.

How does RFID tracking work?

An RFID tag is placed on every asset you want to track.

Then, RFID scanners are strategically placed throughout your facility at all locations that you need to be able to track the assets or operated manually by workers.

The range for automatic scanners is approximately 6000 feet meaning a few well-placed scanners can cover your entire facility.

However, the true value organizations get out of RFID is with software.

Modern, AI-powered software Like Sticker Control can use your data to provide real-time insights you can use to improve your business.

This gives you a global view of your business, allowing you to make sound decisions based on data.

Why should I use RFID tracking?

The major advantages of using RFID is its ability to scan items from a distance, read multiple tags at a time, and send a response within milliseconds.

These advantages add up to a host of benefits your organization could enjoy, including:

Better data – Instead of relying on manual tracking methods which are time consuming and inaccurate, you can always be confident you are collecting the best, most accurate data on your assets.

Increase asset visibility Imagine being able to see the location of your assets in real time and track their progress throughout your operational process. This would reduce security risk, inventory mismanagement, and more.

Decreased labor, space, & time waste – With the insights you gain from RFID tracked data, you can improve and optimize movements of goods and equipment in your facility and increase efficiencies in the movement of employees and the actions they must carry out to complete tasks.

Is RFID a fit for my organization?

If your organization has a component of inventory management or asset tracking, RFID could help massively improve your processes.

For example, a manufacturer might have scanners located throughout your warehouse, production facility, and loading docks to be able to see raw materials enter your facility, go through production, and then get shipped out into your customers waiting hands.

This manufacturer could use the data provided by the RFID system to optimize their warehouse layout so that path the inventory takes and the length of time the inventory spends in each location is as efficient as possible.

Sticker Control has seen RFID help businesses in every sphere imaginable, from manufacturing to rental car agencies.

Read our case studies here for more information:

[How RFID helped a rental car agency get their cars ready-to-rent as quick as possible(https://stickercontrol.com/en/asset-tracking-use-case-rental-car) How RFID helped a manufacturer reduce their shipment error rate

How do I implement RFID tracking?

As you can see, RFID has the potential to save organizations of all types time and money by providing real-time traceability, identification, communication, and location data for people and resources.

To get started, Contact Sticker Control to schedule a free demo.

No Comments